Our commitment to outstanding customer service through strict internal disciplines.

Our skilled and experienced engineers deal with your needs from initial enquiry to the satisfactory delivery of services and products – Leader CNC Technologies becomes your one-stop source for engineering solutions for both prismatic and rotational parts.

We have the ability to integrate CNC control systems with off-line programming and automatic download systems. We also work with established CAD/CAM suppliers to ensure the compatibility of our machine tools with manufacturing / production systems.

Applications & Training

The applications department is skilled in machining and manufacturing methods. They work with various engineering industry sectors and have extensive experience.

We offer a range of services from onsite programming/machining to complete turnkey solutions. The training we offer can be targeted towards machine operators, machine setters, programmers, and maintenance engineers. Through experienced instruction and individual attention in small groups, we achieve a high level of student success.

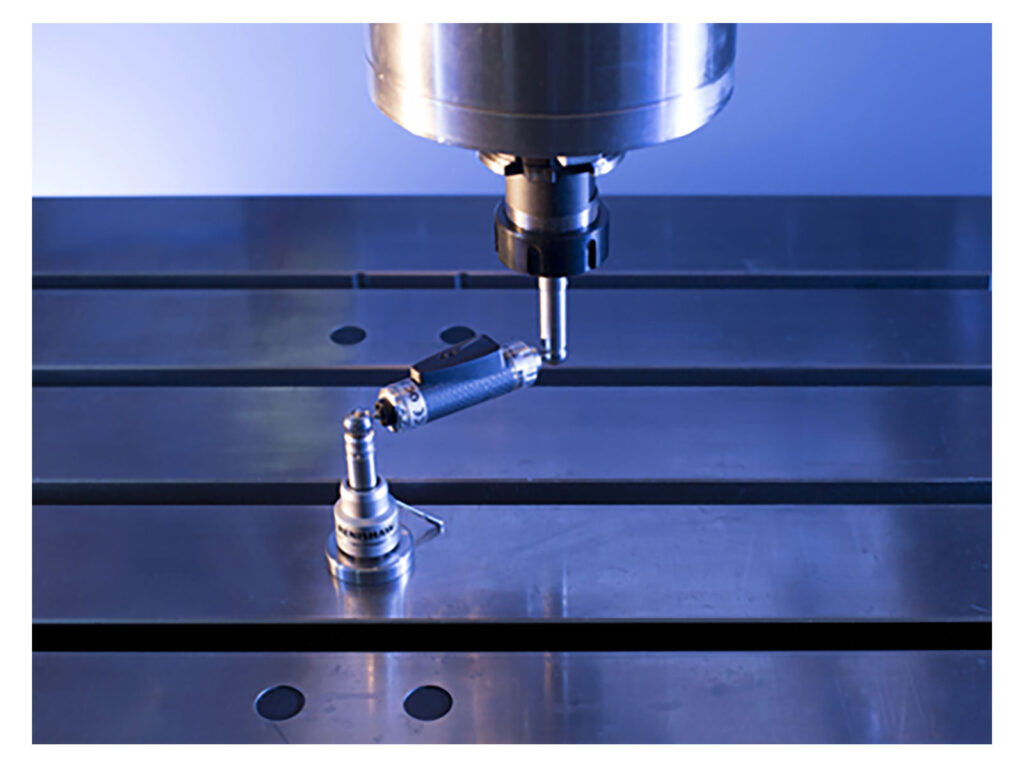

Reinshaw® Ballbar Testing

To ensure your machine geometry is correct and capable of producing accurate components, it’s essential to regularly check and maintain machine performance. Leader CNC Technologies, we offer Renishaw® Ballbar Testing to verify and fine tune the accuracy of your CNC machines.

Ballbar Tests identify geometric issues affecting production quality during routine service or post-move. Using a Renishaw® Ballbar, we evaluate machine accuracy, detect issues like backlash, misalignment, or movement distortions, and provide detailed reports with recommended adjustments.

An accurate machine means higher quality components and less downtime. Let us help you keep your production running smoothly.

Service & Support from Leader CNC

Your one-stop source for engineering solutions

Machine Services

We have a reputation to maintain. Our skilled engineers can fix your machine quickly, whether the breakdown is due to mechanical, electrical, or CNC system faults. We ensure your machine is back to production fast.

We use our own stock and work with specific manufacturers or OEM sources to find parts for many machine tools. We not only locate and provide these parts but also fit them for you. Plus, all our parts and services come with a full warranty, ensuring your machines run smoothly and reliably.

We also offer CNC machine tool relocation using a team of our own engineers and, if necessary, qualified machine movers. We can decommission, move, and recommission machines either locally or to an external site.

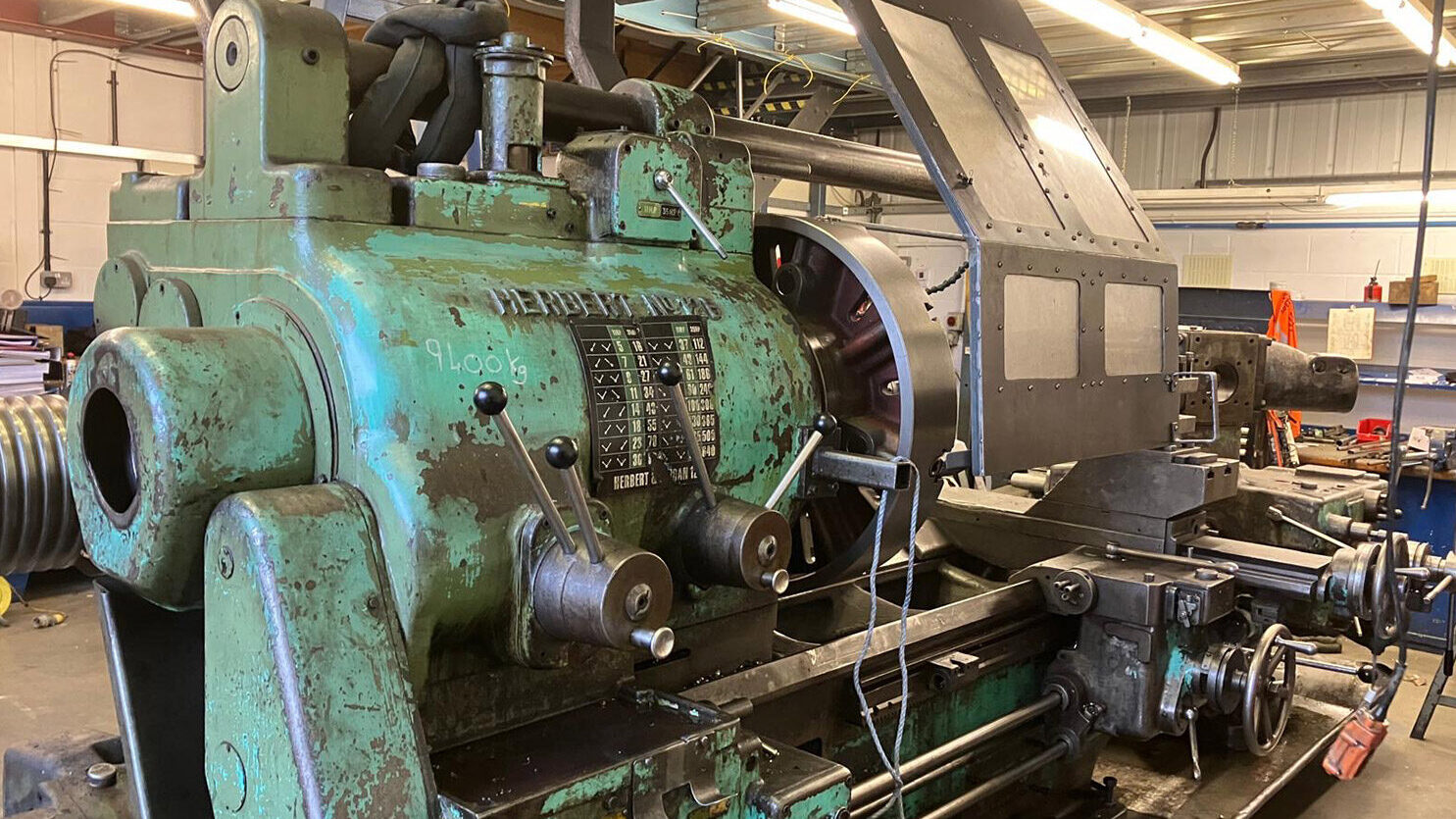

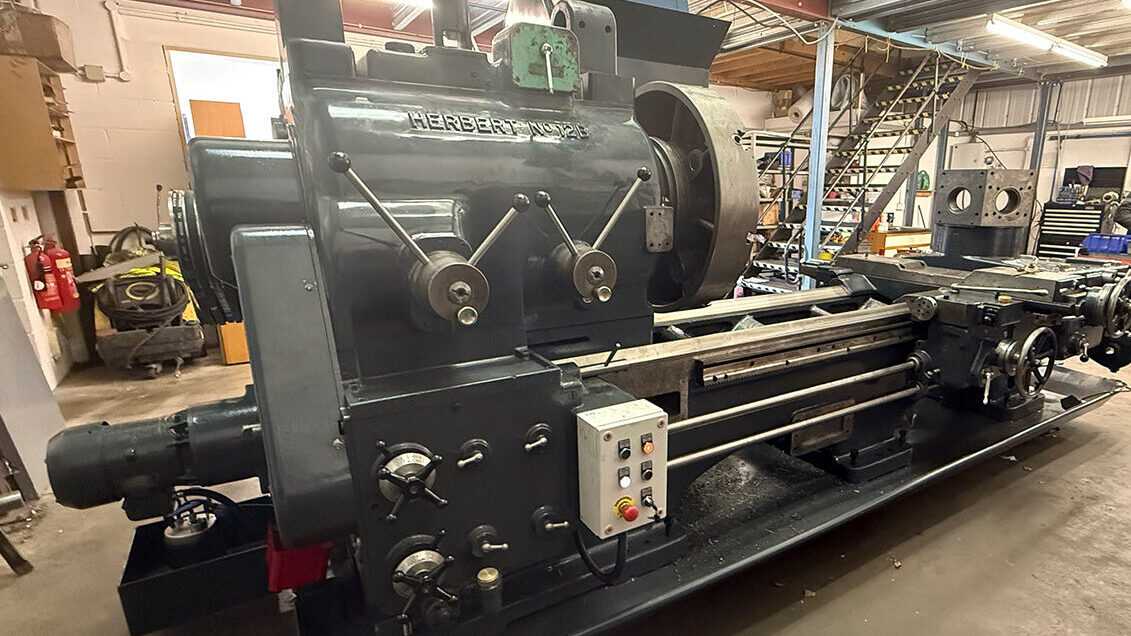

Refurbishments & Rebuilds

Rebuilding or refurbishing of a machine tool can sometimes be more cost effective than purchasing a new equivalent of its type.

Leader CNC Technologies can discuss your rebuild requirements and provide a quote accordingly.

We can complete the rebuild by either leaving your machine on-site and taking away the necessary assemblies, or we can remove the whole machine.

New parts will be sourced or, in some cases, manufactured. The machine tool will be reassembled or reinstalled within your facility and fully tested.

Commissioning & Decommissioning

Whether it’s part of new machine supply, assisting with installation of auction-purchased machines, or after a machine move, we can install and commission machines on site.

Our equipment is calibrated to ISO standards. Before moving a machine, we check its functionality and accuracy. We then give a detailed report to help with re-commissioning.

Laser Calibrations

Laser calibration ensures your CNC machines are accurate and perform optimally. Using advanced laser tech, we measure and align your machine’s geometry to solve production challenges and maintain precision.

Laser calibration improves the accuracy of machines by aligning their axes. This process reduces waste and downtime, making the machines work better. It also saves money by decreasing tool wear and errors. Overall, laser calibration helps machines run more efficiently and cost-effectively.

After laser calibration, we give detailed reports on your machine’s geometry and alignment, serving as a valuable reference for future maintenance and performance records.

Factory Move & Machine Tool Relocation

Leader CNC Technologies offers expert factory move services for our CNC machines and other brands. Whether decommissioning a single machine or relocating an entire factory, our team provides precise, tailored assistance.

Before decommissioning any machine, we produce a detailed geometry report, which includes the following checks to ensure the machine is in optimal condition on reinstallation: machine levelling, spindle runout, squareness of the spindle to the X and Y axes, spindle pull-back force, and chuck clamping pressure.

For an extra cost, we offer ball bar tests before and after moving your machine, ensuring consistent performance. After the move, you’ll get a geometry report detailing the machine’s condition. We also assist with marking out and core drilling for proper installation. Leader CNC excels in efficient, safe, and accurate machine or factory relocations. Trust our team to simplify your next machine move.

Customer Feedback

Frequently asked questions

Here are just some of the common questions we received from clients that are seeking engineering service and support.

Yes, 12 months.

We offer operator, programming and basic maintenance training.

We support most brands of metal cutting CNC machine tools.

Yes we do, please contact us for more details.

Yes we cover both emergency breakdown and repair as well as routine service and maintenance, on most brands.

Yes from full to partial turnkey, contact us for more details.

Yes we work closely with trusted partners for specialist applications and support.

Yes, by special arrangement we offer breakdown cover over holiday periods and shift patterns etc.

Yes, we try to maintain a stock of critical parts, and by special arrangement we can offer bespoke stock holding for your specific machine needs.