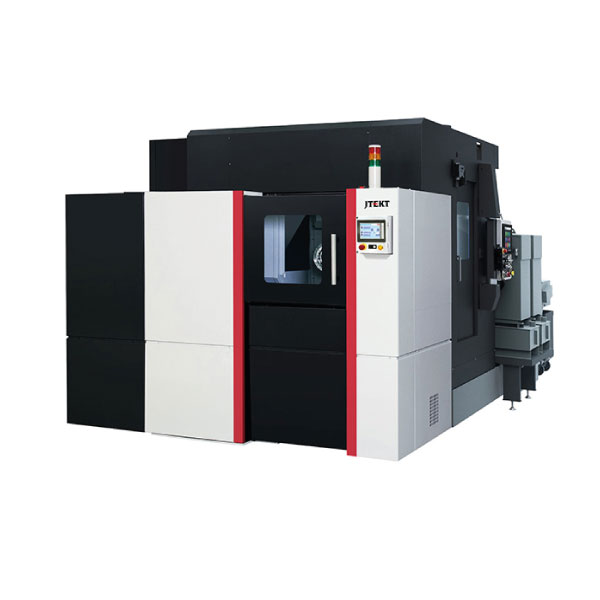

Toyoda's Multitasking Horizontal Machining Centre is the first in the world to equip a skiving function to a general purpose horizontal type machining centre to achieve mass production of gear parts. The GS700H offers improved productivity and flexible machining through high speed cutting and integrated gear part processes of lathe, gear skiving and machining centre capabilities. Offering continuous machining on the shop floor, the GS700H ultimately reduces equipment and cutting tools utilized.

X-Axis Travel 900 mm

Y-Axis Travel 850 mm

Z-Axis Travel 900 mm

Tilt Spindle (A-axis) 100° (+5° ~ -95°)

Rapid Feedrate 20 m/min (X); 36 m/min (Y,Z)

Spindle Nose Shape BBT No.50 (Opt. HSK-A100)

Spindle Speed 50 ~ 6,000 min-1

GS200H

Gear Skiving Centres